Maquinaria para fabricar ladrillos de arenaQT15-15

QT15-15 uses Electro-hydraulic integration technology which is more productive and more profitable than other ordinary block machine; The special vibration and feeding system of this machine can meet the needs of different blocks production for customers., block, grass-planting paver, curb stones, slope-protect bricks, inter-lock blocks and so on.

Suitable height for block: 50-200mm;

Efficient four-axis servo system: Strong power Fast product forming;

Anti-mix color feeding system:Improving the surface quality of pavers;

Airbag clamping: Increase the service life of the mould;

Imported shock pad: shock absorption and noise reduction;

Large pallet design:Super large capacity, More blocks produced

Technical Parameters

Consumption report

|

No. |

Name |

Consumption/hour |

Consumption/8-hour-shift |

Consumption/Day (22 hours) |

Consumption/year (250 days each 22 hour) |

|

1 |

Cement |

8,6 tons |

68,6 tons |

188,8 tons |

47.200 tons |

|

2 |

Sand 0-3mm |

18,6 tons |

148,7 tons |

409 tons |

102.250 tons |

|

3 |

Gravel 3-8mm |

28,6 tons |

228,8 tons |

630 tons |

157.300 tons |

|

4 |

Gravel 8-12mm |

15,7 tons |

125,8 tons |

346 tons |

86.500 tons |

|

5 |

Water (by 100% dry aggregates) |

max. 3.1 m³ |

max. 24,7 m³ |

max. 68 m³ |

max. 17.000 m³ |

Above mentioned mixing recipes are to be used as a guideline only. Optimum mixing recipes depend on type of aggregates locally available and their natural strength. During commissioning of machine,

aggregates are tested and optimum mixing recipes are compiled by the ALFANA service engineers.

Feature

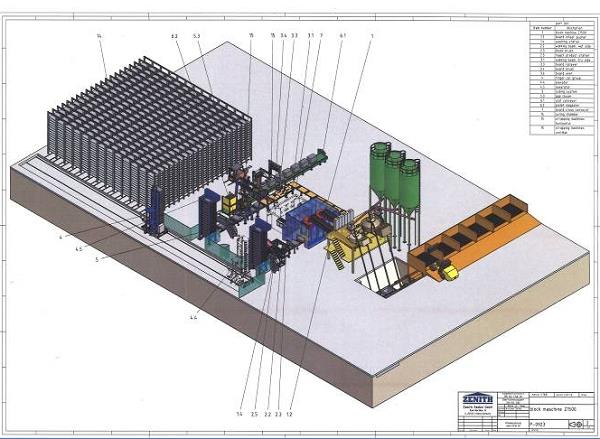

Automatic All-round Cement Brick Machine

QT15-15 has maintenance friendly and matured hydraulic installations on the machine and on the hydraulic station as well as large tank volume. This installation is particularly timesaving in case of maintenance and services thanks to an intelligent layout. All values are located on a maintenance-friendly working height on a service station neat to the block-making machine.

Advantage

1.Quick Mould-changing System

The new electrical bracing of the 2nd filling device is unique on the market. This efficient, electrical solution allows for a quick and safe connection of the machine base part with the 2nd filling device. With this, a safe and fully automatically opening and closing of the 2nd filling device is possible. Quick and short mould change and maintenance times are therefore the major advantages.

2. Scalable Performance

The machine is equipped with scalable performance, meaning it has varieties of convenient and practical program to control the scalable device or equipment, such as Quick Mould-changing System, various color-mixing equipment and Tamperhead Cleaning Device.

Customer Case

QT15-15 in Egypt

The high-performance QT15-15 block machine was built for a large range of production options. Both niche products and standard garden and landscaping products, such as paving stones, curbstones and masonry blocks, can be produced with the machine. The machine is designed for various board sizes from 1,400 x 800 to 1,400 x 1,200 mm, which was designed to be particularly flexible and easy for customers to adapt.

The block making machine is equippedthroughout with Siemens S7-1500 control and switching technology TIA. The machineis networked using ProfiNet and Ethernet.Remote maintenance via the Internet is ofcourse possible. This results in very fastreaction times in the case of problems; solutionsare frequently available within minutes.